Since the 1948, the Kinetic craftsmen and craftswomen, engineers, and salespeople have established and continued to keep Kinetic in its position as the World’s Premier Industrial Knifemaker.

We offer precision-engineered industrial machine knives and hardened wear products, delivered with speed, service, and customization if needed.

Most of our products are manufactured in the U.S. as we value quality above all else, without sacrificing speed with some of the fastest lead times in the industry. Each product is built to the highest standards and manufactured in our ISO-certified facility in Milwaukee, WI.

We continue to invest in new technology yet combine this with years of engineering and experience. We cut, shear, and/or slit materials for the tissue, metals, plastic, wood, recycling, and many other industries. Additionally, we offer full-service contract manufacturing with precision grinding, CNC milling and CNC turning.

Kinetic operated for 7 decades as a family-owned business, and in 2022 joined the Precision Marshall family.

Speed Without Compromise

- We offer the industry’s fastest lead times – without sacrificing quality or precision.

- Stocked products for tissue or nonwovens ship immediately from Wisconsin’s Paper Valley.

- For grinding and sharpening services, we manage your inventory for you.

- We offer contract grinding services that can be turned around when you need it.

Engineered for Quality and Precision

- We engineer every blade to the performance, materials, and needs of your equipment and processes.

- Our XRF Material Analyzer is a key tool upon initial inspection of a customer sample. This allows us to nondestructively evaluate material composition in seconds.

- Kinetic uses a custom made Hardness Tester designed for checking long and unusual shaped parts.

- Custom blade specifications and configurations are available for tissue, metals, packaging, wood, and other industrial machine knife applications.

- Kinetic specializes in working with difficult materials, including tool and high speed steels, powder metal, Inconel, and stainless steel.

- We are ISO 9001:2015 certified, and have operated under an ISO quality management system since 1997.

Made In U.S.A. Industrial Machine Knives

- Our ISO-certified facility is in Milwaukee, WI.

- Trusted by global leaders like P&G, Georgia-Pacific, Nucor Steel and U.S. Steel.

- Recognized by OEMs and mid-market producers alike for performance and personal service.

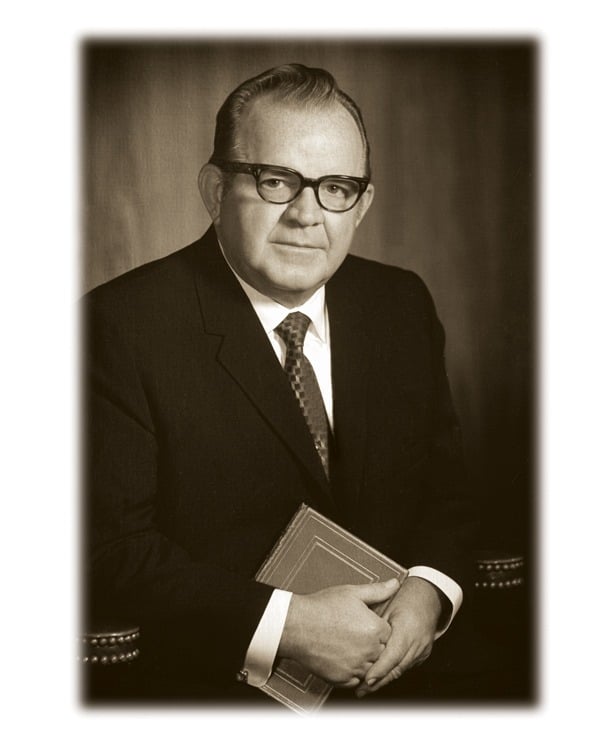

C.L. Masters opens The Kinetic Tool Company to serve the sanitary tissue industry. Manufacturing is done from a small garage.

The Kinetic Tool Company buys a 3600 sq. ft. facility located on the south side of Milwaukee.

The Kinetic Tool Company becomes a leader in the tissue industry for slitters, perforating blades and winding mandrels.

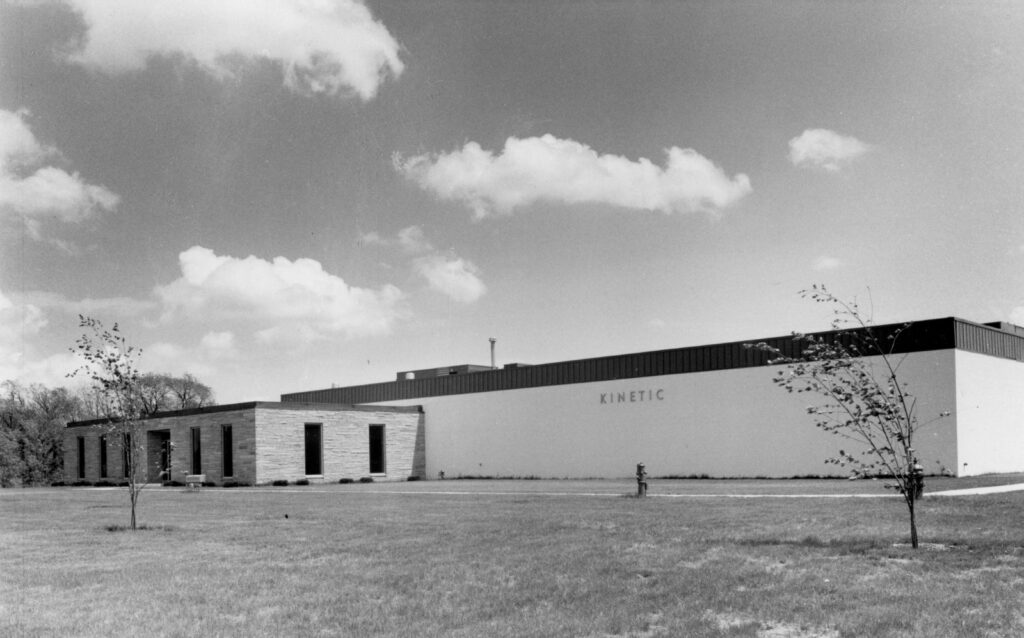

C.L. and his son Joseph purchase a 10 acre parcel located in Greendale, WI. A new 25,000 facility is built, and the company name is changed to The Kinetic Co., Inc. C.L. passes shortly after this move and Joseph takes over running the company.

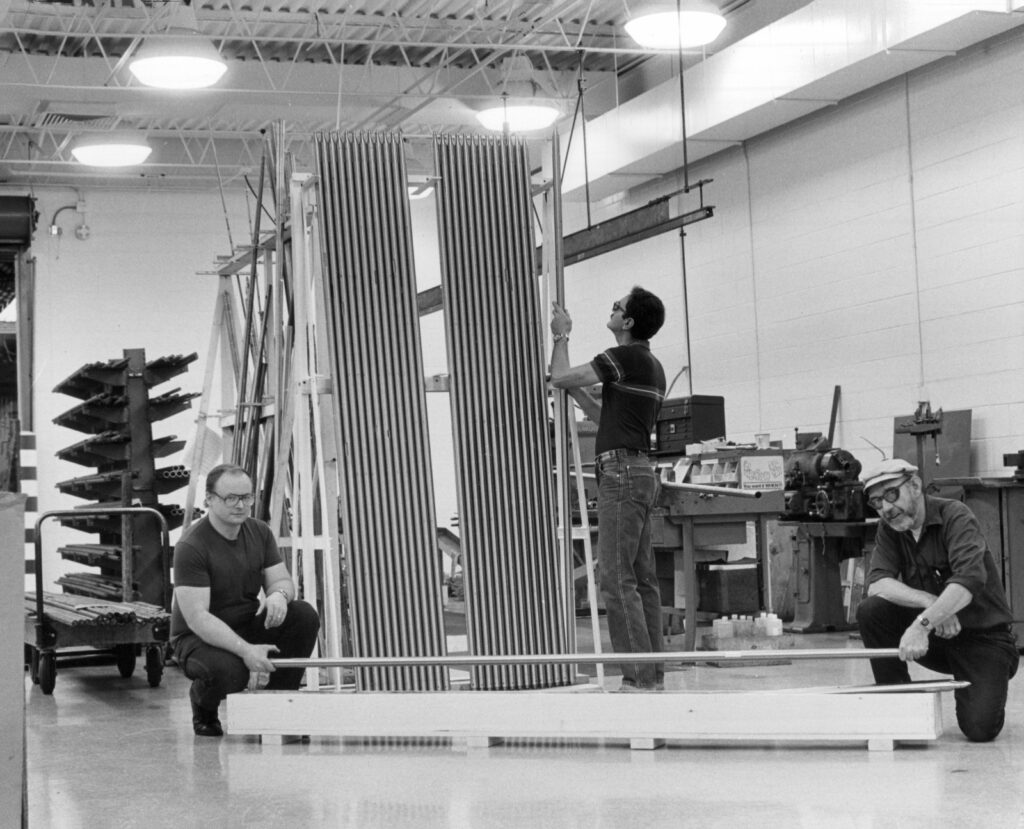

The Kinetic Co., Inc. purchases the slitter and shear blade line from the Tool Steel Gear and Pinion Company in Cincinnati, Ohio. This acquisition expands product line into the metals industry.

This was a decade of continued expansion. There were major expansions to the office and plant for much needed space. The Kinetic Co., Inc. added knives for the wood and recycling industries to its product lineup.

The new millennium brought new global opportunities in the tissue, wood and metals Industry.

Cash Masters, Joseph’s oldest son, leads the expansion into contract manufacturing. A new plant addition with large crane capacity, and the installation of specific grinding and machining equipment was key to this new industry.

The Kinetic Co., Inc. further expands its product offerings in the tissue industry with new products. Heat sealing belts for packaging, and off line grinding for log saws are added due to customer demand for continued improvement in the mills.

Kinetic was acquired by Precision Marshall, based out of Washington, PA.