About us

Kinetic operated for 74 years as a family owned company. In June 2022, Kinetic was acquired by Precision Marshall. Kinetic continues to proudly be known as the World’s Premiere Knifemaker.

We continue to invest in new technology yet combine this with years of engineering and craftsmanship experience. We cut, shear, and/or slit materials for the tissue, metals, plastic, wood and recycling industries. We have the expertise to help you make better cuts and increase your productivity. Better yet, we can prove it.

Our history

The story behind The Kinetic Co., Inc., is a story of entrepreneurial spirit. During the late 1940’s an industrial salesman named C.L. Masters heard many of his northern Wisconsin customers ask if he knew of a source for better quality industrial knives. They repeatedly asked for higher quality knives than were commercially available on the market.

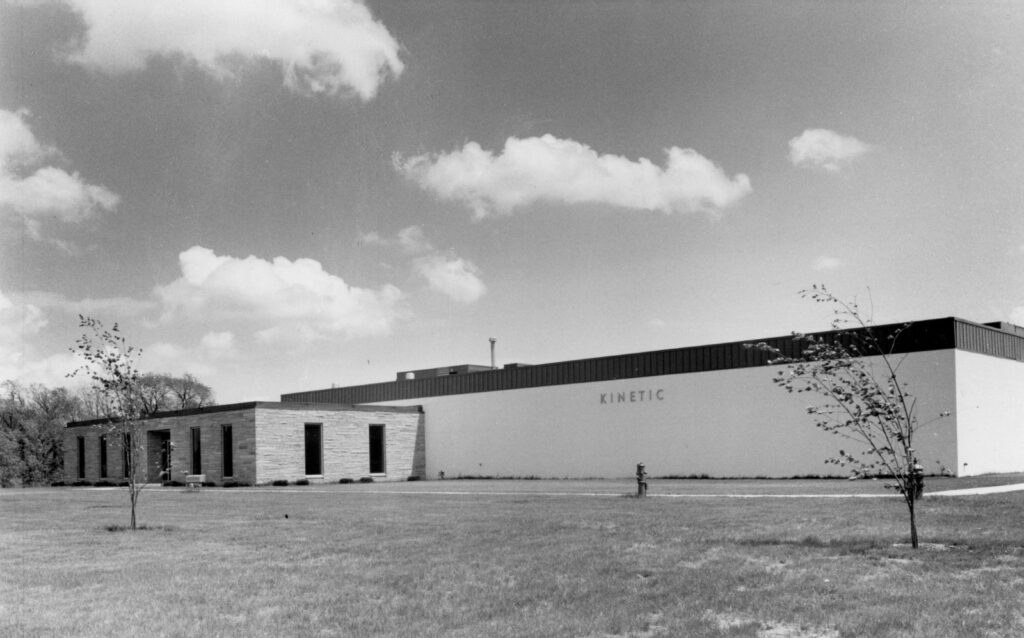

In 1948 working from a small machine shop in his garage C.L. Masters started Kinetic. He dedicated his time and talents to the research and development of a better product and succeeded. Over the course of the next 20 years Kinetic experienced rapid growth and in 1970 Kinetic moved to its current location in Greendale, Wisconsin.

Shortly after moving into the new facility C.L. passed away. His youngest son Joseph was appointed President and over the next 40 years Joseph lead the company thru 3 acquisitions and 6 building expansions. During this time Kinetic continued to invest in modern technology while maintaining the tried and true manufacturing techniques which give Kinetic its edge.

Joseph Masters unexpectedly passed away in 2013 and leadership of Kinetic was assumed by his two sons. Joseph’s oldest son, Cash, who began his career at Kinetic when he was 11 years old, took over the business.

In June of 2022, Live Ventures Incorporated, a diversified holding company, acquired The Kinetic Co., Inc. through its existing subsidiary, Precision Marshall.

The Kinetic team of experienced salespeople, engineers, craftsmen and craftswomen, continue the tradition to keep Kinetic in its position as the “World’s Premier Knifemaker”.

Our history

The story behind The Kinetic Co., Inc., is a story of entrepreneurial spirit. During the late 1940’s an industrial salesman named C.L. Masters heard many of his northern Wisconsin customers ask if he knew of a source for better quality industrial knives. They repeatedly asked for higher quality knives than were commercially available on the market.

In 1948 working from a small machine shop in his garage C.L. Masters started Kinetic. He dedicated his time and talents to the research and development of a better product and succeeded. Over the course of the next 20 years Kinetic experienced rapid growth and in 1970 Kinetic moved to its current location in Greendale, Wisconsin.

Shortly after moving into the new facility C.L. passed away. His youngest son Joseph was appointed President and over the next 40 years Joseph lead the company thru 3 acquisitions and 6 building expansions. During this time Kinetic continued to invest in modern technology while maintaining the tried and true manufacturing techniques which give Kinetic its edge.

Joseph Masters unexpectedly passed away in 2013 and leadership of Kinetic was assumed by his two sons. Joseph’s oldest son, Cash, who began his career at Kinetic when he was 11 years old, took over the business.

In June of 2022, Live Ventures Incorporated, a diversified holding company, acquired The Kinetic Co., Inc. through its existing subsidiary, Precision Marshall.

The Kinetic team of experienced salespeople, engineers, craftsmen and craftswomen, continue the tradition to keep Kinetic in its position as the “World’s Premier Knifemaker”.

Our company

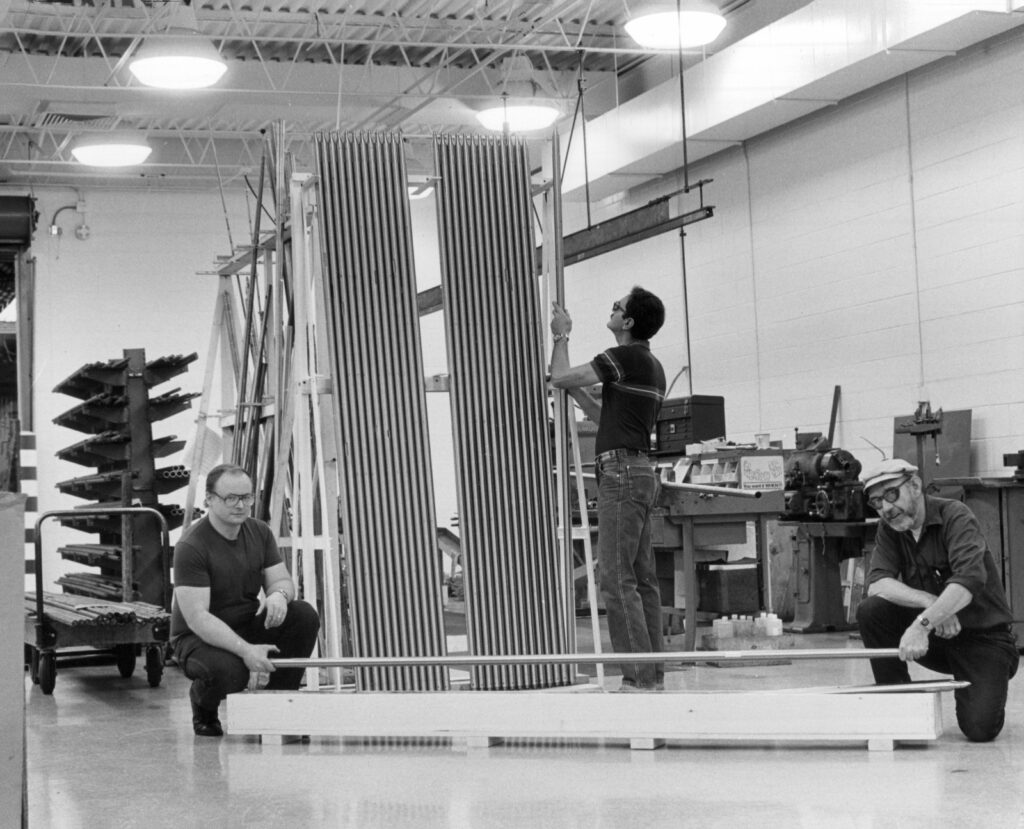

Making the finest industrial knives and hardened wear products requires highly trained employees, the finest metal working equipment available, the best steel melted and rolled, and a facility that is the best in the world. We have all of those at Kinetic.

For those of you who have not had the opportunity to visit us we would like to take you on a tour so that you can learn who we are and what we look like.

Kinetic's historical timeline:

C.L. Masters opens The Kinetic Tool Company to serve the sanitary tissue industry. Manufacturing is done from a small garage.

The Kinetic Tool Company buys a 3600 sq. ft. facility located on the south side of Milwaukee.

The Kinetic Tool Company becomes a leader in the tissue industry for slitters, perforating blades and winding mandrels.

This was a decade of continued expansion. There were major expansions to the office and plant for much needed space. The Kinetic Co., Inc. added knives for the wood and recycling industries to its product lineup.

The new millennium brought new global opportunities in the tissue, wood and metals Industry.

Cash Masters, Joseph’s oldest son, leads the expansion into contract manufacturing. A new plant addition with large crane capacity, and the installation of specific grinding and machining equipment was key to this new industry.

The Kinetic Co., Inc. further expands its product offerings in the tissue industry with new products. Heat sealing belts for packaging, and off line grinding for log saws are added due to customer demand for continued improvement in the mills.

Kinetic was acquired by Precision Marshall, based out of Washington, PA.

Joseph Masters in 1983 at the time of the acquisition of Microblade Limited.

Joseph Masters in 1983 at the time of the acquisition of Microblade Limited.

Our quality

Kinetic currently holds ISO 9001:2015 certification. We have been certified since 1997.

When you are the world leader manufacturing industrial knives the first and last step in the process is quality. The first step involves buying quality material from trusted suppliers.

The next step involves documented steps in the process to manufacture your product. From sales entering your order, to engineering designing the product, and finally our production team manufacturing the product, all steps in the process are managed by the ISO quality process.

Our Niton XRF Material Analyzer is a key tool upon initial inspection of a customer sample. This unit allows us to perform nondestructive material results in seconds. Next to material, heat treating is parallel when discussing quality and performance with industrial knives.

Kinetic uses a custom made Newage Hardness Testor designed for checking long and unusual shaped parts. On the shop floor, each team member has his or her own calibrated inspection tools for use on a daily basis.

Our quality control department has their own tools for final inspection prior to shipment.

Our quality

Kinetic currently holds ISO 9001:2015 certification. We have been certified since 1997.

When you are the world leader manufacturing industrial knives the first and last step in the process is quality. The first step involves buying quality material from trusted suppliers.

The next step involves documented steps in the process to manufacture your product. From sales entering your order, to engineering designing the product, and finally our production team manufacturing the product, all steps in the process are managed by the ISO quality process.

Our Niton XRF Material Analyzer is a key tool upon initial inspection of a customer sample. This unit allows us to perform nondestructive material results in seconds. Next to material, heat treating is parallel when discussing quality and performance with industrial knives.

Kinetic uses a custom made Newage Hardness Testor designed for checking long and unusual shaped parts. On the shop floor, each team member has his or her own calibrated inspection tools for use on a daily basis.

Our quality control department has their own tools for final inspection prior to shipment.