Engineered Log Saw Blades and Tissue Converting Solutions

Tissue Industry Products That Help You Achieve High Productivity

The Kinetic Co. Inc., has a long history of providing the highest quality industrial knives to the Tissue, film and foil industries. Our company was founded in 1948 because the industry needed better knives to replace what was currently available in the marketplace at that time. Kinetic was the first manufacturer to apply advanced, high-speed steels to improve the performance of knives in these industries.

As industry technology has progressed, so have Kinetic industrial knives. Today, our material expertise is the best in the knife industry. Our on-staff knife experts match the right knife material to your application. Then, we provide an uncompromising heat-treating and finishing process that results in consistent, accurate knives that provide high productivity and cost-effective performance.

Kinetic has expanded our product offering allowing us to provide more solutions for tissue, towel, napkin, sanitary, non-woven, wipes, packaging, and wrapping applications. We now offer roll services, which includes new rolls, repairs and recoating.

Tissue blades / Nonwoven blades

Tissue Industry Products That Help You Achieve High Productivity

The Kinetic Co. Inc., has a long history of providing the highest quality industrial knives to the Tissue, film and foil industries. Our company was founded in 1948 because the industry needed better knives to replace what was currently available in the marketplace at that time. Kinetic was the first manufacturer to apply advanced, high-speed steels to improve the performance of knives in these industries.

As industry technology has progressed, so have Kinetic industrial knives. Today, our material expertise is the best in the knife industry. Our on-staff knife experts match the right knife material to your application. Then, we provide an uncompromising heat-treating and finishing process that results in consistent, accurate knives that provide high productivity and cost-effective performance.

Kinetic has expanded our product offering allowing us to provide more solutions for tissue, towel, napkin, sanitary, non-woven, wipes, packaging, and wrapping applications. We now offer roll services, which includes new rolls, repairs and recoating.

Perf Blades, Anvils, and Associated Parts

Kinetic has been manufacturing perf blades for tissue manufacturers around the world since 1955. We solve our customers’ production issues by helping to select the bond pattern and blade configuration best suited to specific production requirements.

• Standard PCMC 4.4xx” perf blade

• Standard PCMC design carbide anvils

• Long Korleus style and Ital style Bi-Metallic perf blades and anvils

• Perini/Futura style Bi-Metallic long and segmental perf blades and anvils

• Match Ground Bi-Metallic blades

High wear resistance, Superb toughness

• Available from stock deliveries to increase your machine uptime.

• Regrinding service provides additional service life from your anvils to decrease your costs.

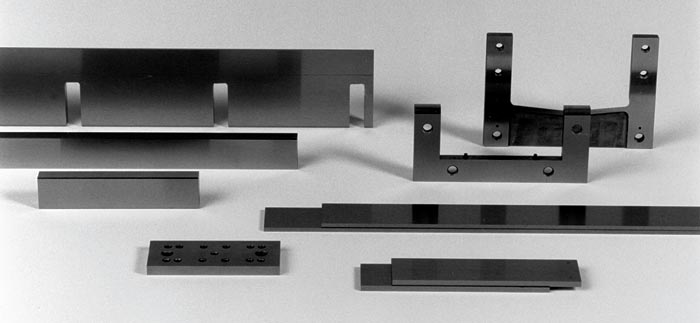

Fly Knives and Anvils

Kinetic offers a wide variety of fly knives that have been developed for use with the most popular models of napkin folding machines. All of our fly knives meet or exceed OEM standards.

The materials that we use in the manufacture of our fly knives include MM high-speed steel and Ultra-Wear Particle Metallurgy material. And, because we are design experts in the paper converting industry, we can provide fly knives with extremely accurate chamfers to ensure consistent shear cut off. Let Kinetic save you the time and expense of installing the chamfers yourself.

• Kinetic’s finish grind manufacturing processes ensure correct flatness and parallels.

• The accuracy of Kinetic’s knives ensures ease of adjustment, installation and long service life in your operation.

Cut-Off Blades

Kinetic has been working directly with diaper machinery manufacturers and customers to develop the best diaper knives and cut-off blades in the industry. Based on our many years of experience, we have optimized material choices, perfected heat treatments and finish grinding techniques to provide you with industrial knife products that are wear-resistant and tough.

Depending on the application and the speed of the machine, Kinetic cut-off blades are manufactured from high-tech materials such as MM high-speed steel, VC high-speed steel, Ultra-Wear Particle Metallurgy material and tungsten carbide.

• Configured to fit all major types of diaper, fem-hy and adult incontinence machinery.

• Meets or exceeds OEM specifications.

• Most available in stock.

Winding Mandrels, Making Mandrels, Core Winding / Cutting Mandrels – New, Rebuilds, and Parts

Our mandrel and shaft manufacturing program begins with aircraft quality tube stock and ends with a three-plane dynamics balancing process that allow us to certify our mandrels to .002″ (0.05mm) peak to peak displacement amplitude.

Components that we use in our winding mandrel assembly meet or exceed OEM specifications. Using Kinetic Winding Mandrels, Making Mandrels and Core Shafts in your paper processing applications guarantees long service life and trouble-free performance on your shop floor.

• Mandrels for non-water cooled and water-cooled applications in the composite can industry.

• Heat treating and plating process used for making mandrels increases service life and component performance.

• Custom designed and manufactured winding mandrels and making mandrels to suit your specific application and production requirements.

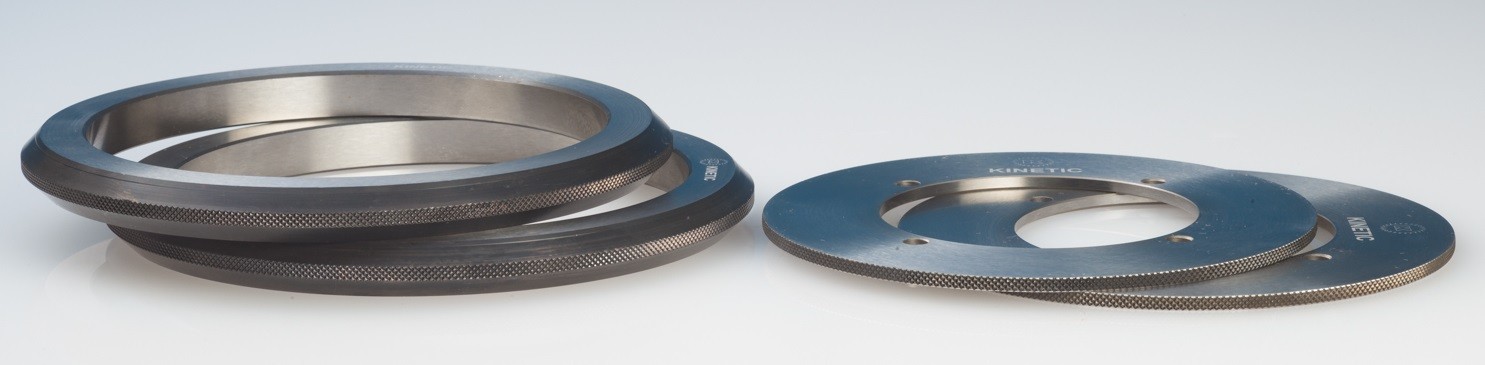

Core Cutter Blades – All types and Sizes for Any Application

The Kinetic Co., Inc., manufactures all types and sizes of tube cutter blades, core cutter blades and core saws, most of which are usually available for immediate shipment from stock.

• Crush cut small diameter blades

• Crush cut larger diameter (Perini) blades

• Shark tooth standard blades

• Tungsten carbide tipped blades

Each blade is manufactured to Kinetic’s highest standards. The result is high precision blades with excellent concentricity for smooth cuts and a high surface finish, which improves service life while reducing dusting.

• Manufactured from either tool steel or high-speed steels for additional wear-resistance and toughness.

• Heat-treated to meet the most rigorous demands of your application.

Slitters

With experience going back to 1960 in manufacturing slitters and slitter anvil sleeves, you can be sure that Kinetic offers the best slitter and anvil products in the industry to boost your productivity.

With our superb manufacturing processes, including in-house heat treatment, Kinetic manufactures the highest quality slitters in the industry for any slitting application.

• Flat slitters

• Dished slitters

• Hardened slitters

• Shear slitters

• Crush cut slitters

Slitter Anvils – In Stock or Custom-Made

Our Hardened Sleeves and Anvils are made from through-hardened tool steels heat-treated 2-4 points harder than the shear slitters or crush cutter slitters against them to ensure maximum service live. Through-hardened rather than surface hardened sleeves and anvils, so they can be reground or resurfaced many times to extend their service life.

• Inside diameters are sized to perfectly match the specifications of your shaft.

• Ends are manufactured to be perpendicular or squared to within .001″ (.025 mm) to provide a perfect, “seamless” fit.

Split Band Bottom Slitter Anvils

Upgrading to split band bottom slitter bands in your operation results in a very fast ROI due the dramatic drop in machine downtime. Instead of having to pull the shaft and slide the anvils off – often talking hours – you unbolt the dull anvils and replace them in minutes.

- Use of D-2 and/or tungsten carbide eliminates frequent regrinding, saving you time and protecting your knife investment.

- Through-hardened to enhance wear resistance and toughness.

- Precision machined, finish ground and super finished to provide minimum lateral runout and excellent concentricity, while enhancing the performance of the top shear slitter blade used against the bands.

- Super finish and edge sharpness minimizes dust production and improves cut quality.

- Available for any machine where the bottom slitter anvil is shaft mounted.

Multi-Knife Block Slitter Bands

Multi-knife block slitter bands are a time-saving solution for applications with fixed pitches requiring multiple slitting widths. Your downtime is reduced since there’s no need to move the anvils when changing to a different width product.

Multi-knife block slitter bands are also available from Kinetic in split band designs.

Hardened Anvil Rolls / Hardened Anvil Sleeves

Kinetic has been manufacturing hardened anvil rolls and hardened anvil sleeves from through-hardened tool steels since the 1950s. Because we utilize the best metals and alloys for our products, they can be reground or resurfaced without the damage that can be caused from going through a surface hardened or case hardened knife.

Kinetic hardened anvil rolls and hardened anvil sleeves are 2-4 points harder than the slitters or crush cutters that are cutting against them to maximize service life and provide you with consistent cutting action.

• Quality knife materials ensure long service life.

• Kinetic’s vast experience allows us to manufacture virtually any hardened anvil roll or sleeve for any application.

Solid AISI D-2 Thru Hardened Anvil Roll for Heavy-Duty Applications

Ply Bonders / Crimper Wheels

The Kinetic Co., Inc., scored another industry first when we initiated the manufacture of Ply-Bonders / Crimper Wheels from through-hardened high carbon, high chrome tool steel. This specialized material maximizes service life and enhances crimping performance in your operation.

Our on-staff design experts have developed a proprietary pattern for our Ply-Bonders/Crimper Wheels that has been extremely successful in ply-bonding multiple ply products.

• In-house vacuum heat treating process provides long service life and outstanding durability.

• Custom ply-bond patterns tailored to your application.

Chopper Blades / Bed Roll Knives

/ Bed Roll Pins

Kinetic has been manufacturing chopper blades for tissue converters around the world since 1955.

In recent years, Kinetic has developed a new generation of high performance chopper blades to meet your demanding applications.

• New tooth designs and blade configurations for improved cut quality.

• Advanced materials and production methods for all demanding applications.

• Process auditing and consulting services for specific applications and recommendations for improved runnability.

• Truly innovative post-manufacturing treatments to improve cut-off quality and promote cleaner operation for hard-to-cut/reinforced webs, etc.

Perf Blades, Anvils, and Associated Parts

Kinetic has been manufacturing perf blades for tissue manufacturers around the world since 1955. We solve our customers’ production issues by helping to select the bond pattern and blade configuration best suited to specific production requirements.

• Standard PCMC 4.4xx” perf blade

• Standard PCMC design carbide anvils

• Long Korleus style and Ital style Bi-Metallic perf blades and anvils

• Perini/Futura style Bi-Metallic long and segmental perf blades and anvils

• Match Ground Bi-Metallic blades

High wear resistance, Superb toughness

• Available from stock deliveries to increase your machine uptime.

• Regrinding service provides additional service life from your anvils to decrease your costs.

Perf Blades, Anvils, and Associated Parts

Kinetic has been manufacturing perf blades for tissue manufacturers around the world since 1955. We solve our customers’ production issues by helping to select the bond pattern and blade configuration best suited to specific production requirements.

• Standard PCMC 4.4xx” perf blade

• Standard PCMC design carbide anvils

• Long Korleus style and Ital style Bi-Metallic perf blades and anvils

• Perini/Futura style Bi-Metallic long and segmental perf blades and anvils

• Match Ground Bi-Metallic blades

High wear resistance, Superb toughness

• Available from stock deliveries to increase your machine uptime.

• Regrinding service provides additional service life from your anvils to decrease your costs.

Fly Knives and Anvils

Kinetic offers a wide variety of fly knives that have been developed for use with the most popular models of napkin folding machines. All of our fly knives meet or exceed OEM standards.

The materials that we use in the manufacture of our fly knives include MM high-speed steel and Ultra-Wear Particle Metallurgy material. And, because we are design experts in the paper converting industry, we can provide fly knives with extremely accurate chamfers to ensure consistent shear cut off. Let Kinetic save you the time and expense of installing the chamfers yourself.

• Kinetic’s finish grind manufacturing processes ensure correct flatness and parallels.

• The accuracy of Kinetic’s knives ensures ease of adjustment, installation and long service life in your operation.

Cut-Off Blades

Kinetic has been working directly with diaper machinery manufacturers and customers to develop the best diaper knives and cut-off blades in the industry. Based on our many years of experience, we have optimized material choices, perfected heat treatments and finish grinding techniques to provide you with industrial knife products that are wear-resistant and tough.

Depending on the application and the speed of the machine, Kinetic cut-off blades are manufactured from high-tech materials such as MM high-speed steel, VC high-speed steel, Ultra-Wear Particle Metallurgy material and tungsten carbide.

• Configured to fit all major types of diaper, fem-hy and adult incontinence machinery.

• Meets or exceeds OEM specifications.

• Most available in stock.

Winding Mandrels, Making Mandrels, Core Winding / Cutting Mandrels – New, Rebuilds, and Parts

Our mandrel and shaft manufacturing program begins with aircraft quality tube stock and ends with a three-plane dynamics balancing process that allow us to certify our mandrels to .002″ (0.05mm) peak to peak displacement amplitude.

Components that we use in our winding mandrel assembly meet or exceed OEM specifications. Using Kinetic Winding Mandrels, Making Mandrels and Core Shafts in your paper processing applications guarantees long service life and trouble-free performance on your shop floor.

• Mandrels for non-water cooled and water-cooled applications in the composite can industry.

• Heat treating and plating process used for making mandrels increases service life and component performance.

• Custom designed and manufactured winding mandrels and making mandrels to suit your specific application and production requirements.

Core Cutter Blades – All types and Sizes for Any Application

The Kinetic Co., Inc., manufactures all types and sizes of tube cutter blades, core cutter blades and core saws, most of which are usually available for immediate shipment from stock.

• Crush cut small diameter blades

• Crush cut larger diameter (Perini) blades

• Shark tooth standard blades

• Tungsten carbide tipped blades

Each blade is manufactured to Kinetic’s highest standards. The result is high precision blades with excellent concentricity for smooth cuts and a high surface finish, which improves service life while reducing dusting.

• Manufactured from either tool steel or high-speed steels for additional wear-resistance and toughness.

• Heat-treated to meet the most rigorous demands of your application.

Slitters

With experience going back to 1960 in manufacturing slitters and slitter anvil sleeves, you can be sure that Kinetic offers the best slitter and anvil products in the industry to boost your productivity.

With our superb manufacturing processes, including in-house heat treatment, Kinetic manufactures the highest quality slitters in the industry for any slitting application.

• Flat slitters

• Dished slitters

• Hardened slitters

• Shear slitters

• Crush cut slitters

Slitter Anvils – In Stock or Custom-Made

Our Hardened Sleeves and Anvils are made from through-hardened tool steels heat-treated 2-4 points harder than the shear slitters or crush cutter slitters against them to ensure maximum service live. Through-hardened rather than surface hardened sleeves and anvils, so they can be reground or resurfaced many times to extend their service life.

• Inside diameters are sized to perfectly match the specifications of your shaft.

• Ends are manufactured to be perpendicular or squared to within .001″ (.025 mm) to provide a perfect, “seamless” fit.

Split Band Bottom Slitter Anvils

Upgrading to split band bottom slitter bands in your operation results in a very fast ROI due the dramatic drop in machine downtime. Instead of having to pull the shaft and slide the anvils off – often talking hours – you unbolt the dull anvils and replace them in minutes.

- Use of D-2 and/or tungsten carbide eliminates frequent regrinding, saving you time and protecting your knife investment.

- Through-hardened to enhance wear resistance and toughness.

- Precision machined, finish ground and super finished to provide minimum lateral runout and excellent concentricity, while enhancing the performance of the top shear slitter blade used against the bands.

- Super finish and edge sharpness minimizes dust production and improves cut quality.

- Available for any machine where the bottom slitter anvil is shaft mounted.

Multi-Knife Block Slitter Bands

Multi-knife block slitter bands are a time-saving solution for applications with fixed pitches requiring multiple slitting widths. Your downtime is reduced since there’s no need to move the anvils when changing to a different width product.

Multi-knife block slitter bands are also available from Kinetic in split band designs.

Hardened Anvil Rolls / Hardened Anvil Sleeves

Kinetic has been manufacturing hardened anvil rolls and hardened anvil sleeves from through-hardened tool steels since the 1950s. Because we utilize the best metals and alloys for our products, they can be reground or resurfaced without the damage that can be caused from going through a surface hardened or case hardened knife.

Kinetic hardened anvil rolls and hardened anvil sleeves are 2-4 points harder than the slitters or crush cutters that are cutting against them to maximize service life and provide you with consistent cutting action.

• Quality knife materials ensure long service life.

• Kinetic’s vast experience allows us to manufacture virtually any hardened anvil roll or sleeve for any application.

Solid AISI D-2 Thru Hardened Anvil Roll for Heavy-Duty Applications

Ply Bonders / Crimper Wheels

The Kinetic Co., Inc., scored another industry first when we initiated the manufacture of Ply-Bonders / Crimper Wheels from through-hardened high carbon, high chrome tool steel. This specialized material maximizes service life and enhances crimping performance in your operation.

Our on-staff design experts have developed a proprietary pattern for our Ply-Bonders/Crimper Wheels that has been extremely successful in ply-bonding multiple ply products.

• In-house vacuum heat treating process provides long service life and outstanding durability.

• Custom ply-bond patterns tailored to your application.

Chopper Blades / Bed Roll Knives

/ Bed Roll Pins

Kinetic has been manufacturing chopper blades for tissue converters around the world since 1955.

In recent years, Kinetic has developed a new generation of high performance chopper blades to meet your demanding applications.

• New tooth designs and blade configurations for improved cut quality.

• Advanced materials and production methods for all demanding applications.

• Process auditing and consulting services for specific applications and recommendations for improved runnability.

• Truly innovative post-manufacturing treatments to improve cut-off quality and promote cleaner operation for hard-to-cut/reinforced webs, etc.

Contact us